From Scrap to Sustainability - The Gravita Lithium Battery Recycling Process

A closed-loop system that recovers critical minerals, protects the planet and powers the next generation of clean energy.

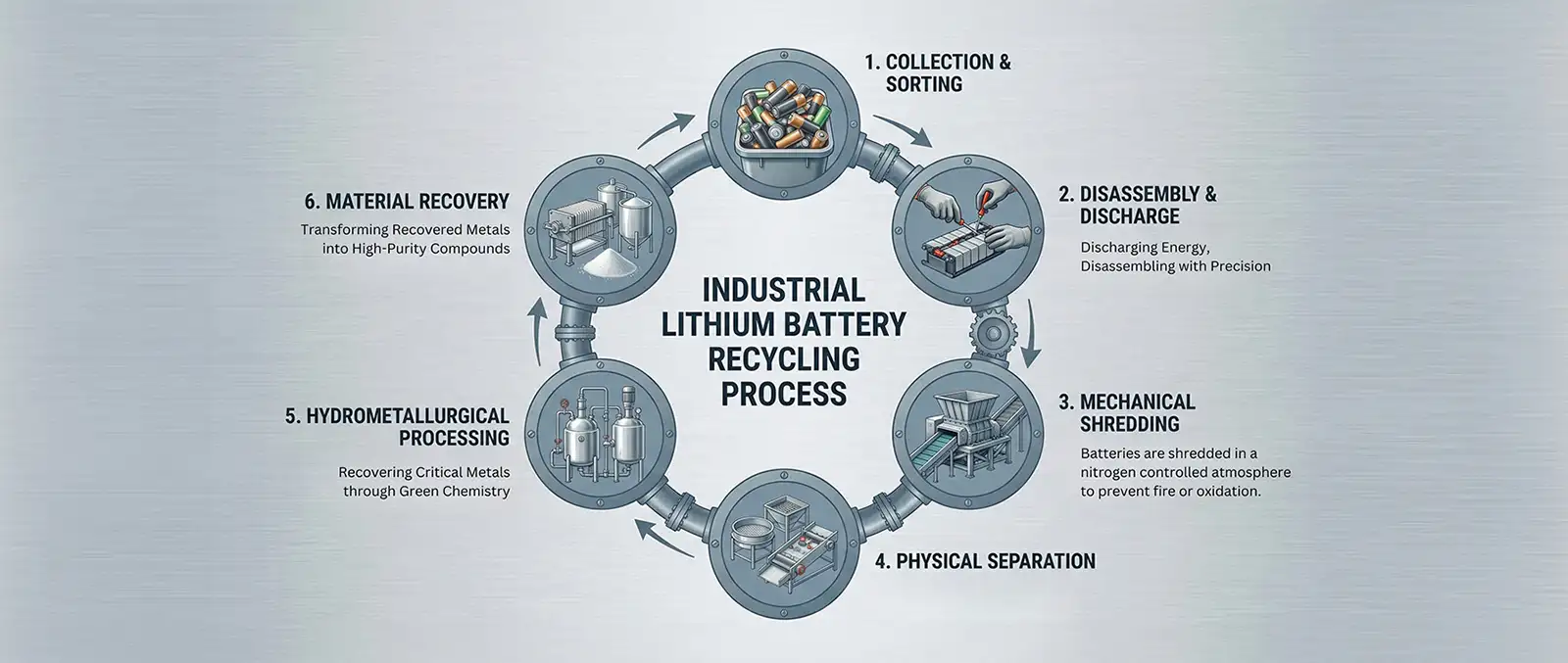

Gravita’s Lithium Battery Recycling process integrates mechanical, hydrometallurgical, and environmental technologies to ensure maximum recovery with minimal environmental impact.

Our end-to-end process is designed to safely handle complex chemistries and produce high-purity materials ready for reuse in manufacturing.

Collection & Sorting

Collecting End-of-Life Batteries from Diverse Sources

We collect used Lithium-ion batteries from:

- Electric and hybrid vehicles

- Consumer electronics (phones, laptops, power banks)

- Energy storage systems (ESS, solar, grid-scale)

Each battery type is identified, logged and sorted by chemistry - LFP, NMC, LCO, or others - ensuring safe and efficient downstream processing.

Safe Discharging & Dismantling

Discharging Energy, Disassembling with Precision

To eliminate any residual charge, batteries are safely discharged under controlled conditions.

Automated dismantling lines separate key components:

- Casings

- Modules and cells

- Busbars, plastics, and circuit boards

All recovered materials are directed for specialized recycling or reuse.

Screening & Refurbishing

Assessing Health, Extending Lifecycles

Not every battery has reached the end of its road. We conduct rigorous diagnostic testing on dismantled modules to determine their viability for second-life applications before recycling.

Our evaluation process involves:

- Precision testing to measure remaining capacity.

- Categorizing modules for less intensive applications (e.g., stationary storage).

- Diverting healthy modules for re-assembly into second-life packs.

Only modules that fall below efficiency thresholds are sent for mechanical shredding, ensuring reuse is prioritized over material recovery.

Mechanical Shredding

Breaking Down Batteries into Valuable Fractions

Cells are shredded in an inert atmosphere (nitrogen-controlled) to prevent fire or oxidation.

Multi-stage sieving separates:

- Black Mass (contains Li, Ni, Co, Mn)

- Copper & Aluminium Foils

- Plastics and Ferrous Metals

All fractions move forward for recovery or material recycling.

Hydrometallurgical Extraction

Recovering Critical Metals through Green Chemistry

The heart of the process where black mass undergoes hydrometallurgical refining:

- Leaching: Dissolving metals using eco-safe solvents

- Purification: Removing impurities and unwanted residues

- Precipitation: Extracting pure metal salts

- Filtration & Crystallization: Generating high-purity compounds

This closed-loop system achieves >90% recovery efficiency, minimizing chemical waste and emissions.

Refining & Conversion

Transforming Recovered Metals into High-Purity Compounds

Recovered metals are refined into industrial-grade products such as:

- MHP (Mixed Hydroxide Precipitate)

- Iron Phosphate

- Nickel-Cobalt Concentrates

- Lithium Carbonate and Lithium Hydroxide (in development)

Each compound meets battery-grade purity standards and is ready for reuse by OEMs and cathode manufacturers.

Waste Treatment & Circular Recovery

Closing the Loop with Zero Waste and Full Traceability

Every byproduct is neutralized, filtered, or reused.

- Wastewater is treated and recirculated (Zero Liquid Discharge).

- Emissions are captured through multi-stage filtration.

- Every recovered gram is traceable — from scrap to final compound.

The process ensures complete environmental compliance and contributes directly to the circular economy.