Explore Our Recycling Solutions

Key Features

Latest Stories

Stay up to date with the latest news from Gravita India Ltd.

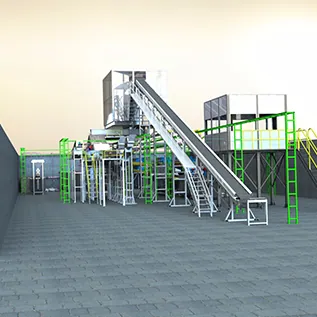

Our comprehensive turnkey solutions provide efficient and convenient recycling processes and solutions for recycling lead, aluminium, plastic, copper, and rubber. As a leading provider in the industry, we offer turnkey projects for smelting, refining, and recycling, ensuring optimal results and contributing to a sustainable future. Moreover, our solutions are designed to keep the low cost of ownership in mind, making recycling accessible and economically viable for businesses of all sizes.

Our turnkey projects are designed to not only facilitate maximum production capacity within a two-to-three month timeframe, but also to provide our customers with consistency in productivity and enhanced safety for their workforce. We understand the specific needs of small to medium-scale processing units and provide customised services that prioritise timely delivery and effective pollution control. Our eco-friendly plants are cost-effective and fully compliant with ISO 9001 and ISO 14000 guidelines, as well as technical and regulatory standards, guaranteeing reliable and environmentally-conscious solutions.

When you choose our turnkey solutions, you can be confident that your production will run continuously, and your workforce will benefit from a safe and secure environment.

Assistance and supervision during plant erection

Battery recycling technology

Commissioning of the plant

Complete supply of plant and machinery

Designing & retrofitting of existing pollution control plant / Battery recycling plant

Establishment of quality concerning process and product

Layout and composite engineering design for the plants

Lead sub-oxide, red lead & litharge manufacturing plants

PLC-based control & monitor system for advanced setups

Pollution control systems for various industries

Provide information and training to personnel

Recycling technology

Refining, alloying techniques & equipment

Technical consultancy & services

Stay up to date with the latest news from Gravita India Ltd.

We have updated our policy. By continuing to browse this website, you agree to our privacy policy and the use of cookies on the website.